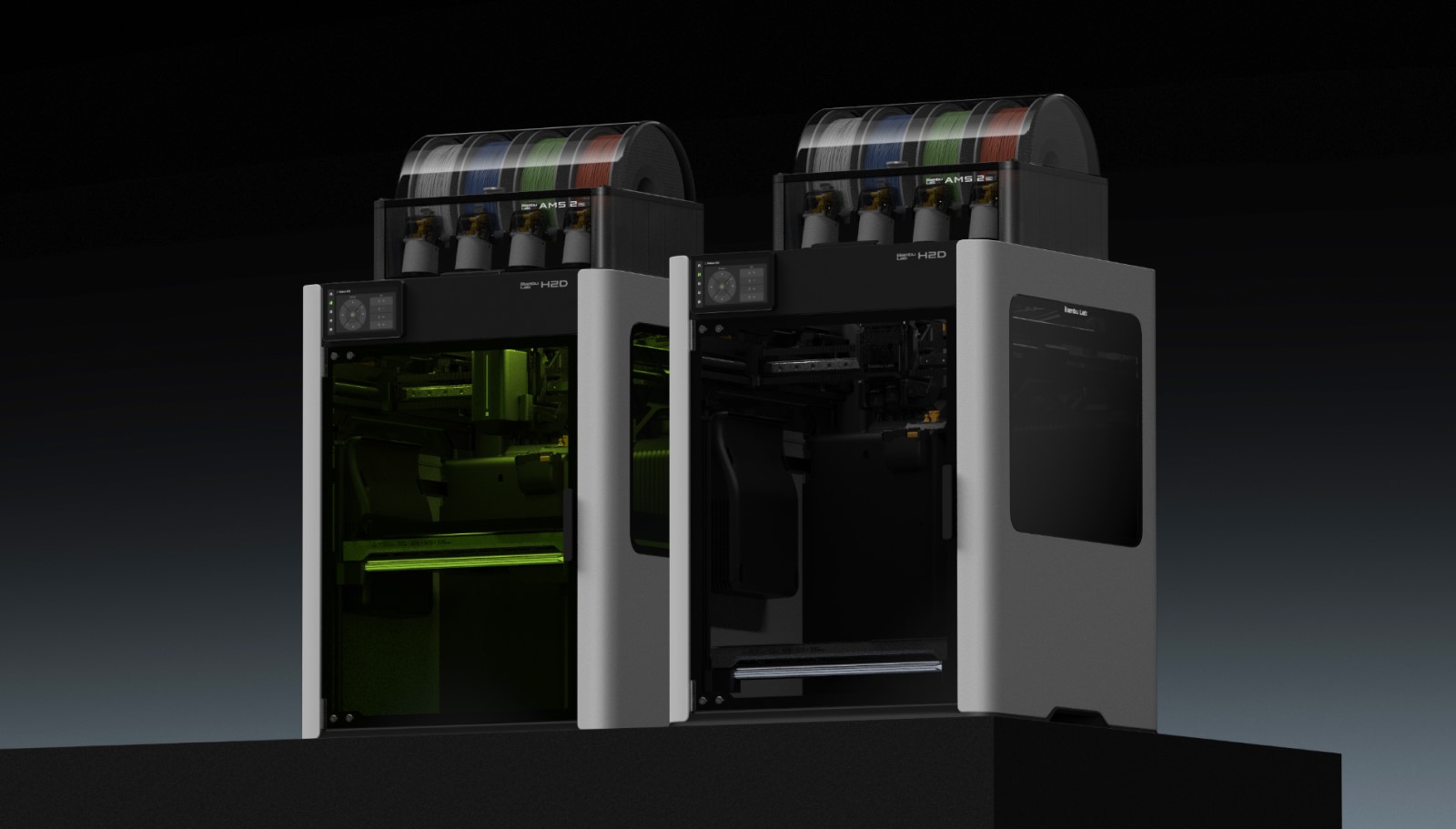

Bambu Lab H2D 3D Printer

Bambu Lab H2D

The Bambu Lab H2D is a dual-nozzle powerhouse, purpose-built for personal manufacturing with industry-grade reliability. With an enclosed, actively heated chamber reaching up to 65°C and a maximum nozzle temperature of 350°C, it’s designed to handle the most demanding materials like PPA-CF, PPS, and engineering-grade filaments. Dual extrusion enables seamless printing with support materials or multi-color jobs, while intelligent sensors and AI-powered extrusion control ensure every print is perfect from start to finish.

Built around a robust aluminum and steel chassis, the H2D combines speed, accuracy, and safety in one sleek platform. With built-in air purification, real-time smart monitoring, advanced slicing software, and multi-mode capabilities (laser, pen, cutter), the H2D is your all-in-one personal fabrication tool. From industrial prototyping to creative exploration — the H2D is built for it all.

Plug and Print

Out of the box to your first print in minutes

Unbox, plug in, and print — the H2D is ready to go with full-auto calibration, dual-nozzle alignment, and smart filament management. It handles first-layer calibration, material detection, and even filament tangles with built-in sensors and recovery logic.

Maximum Performance

Dual-nozzle precision and blazing speed

Print up to 1000 mm/s with a 40 mm³/s flow rate and accelerate at 20,000 mm/s². The H2D delivers unmatched productivity with minimal material waste thanks to optimized purge and toolpath logic. Hardened steel gears, AI extrusion control, and a TRUE high-flow hotend deliver speed without sacrificing quality.

Advanced Material Compatibility

Print everything from PLA to PPS-CF

Equipped with a 65°C actively heated chamber and hardened components, the H2D handles technical materials with ease — from flexible TPU to carbon fiber-reinforced filaments. Dedicated dual-nozzle printing allows full support material compatibility (PVA/BVOH), eliminating the need for compromise.

Smarter Printing

AI-enhanced monitoring and material recognition

From pre-flight checks to live error detection, the H2D is packed with intelligent monitoring features. A suite of cameras and 15+ sensors track filament flow, nozzle position, and environmental conditions — ensuring every layer is perfect. QR Code-based filament profiles and onboard diagnostics make setup and maintenance effortless.

Multi-Tool Capable

Laser, Cutting, Drawing — All in One

Expand your H2D with modular add-ons like a 10W/40W laser engraver, precision cutting module, and pen plotter. Combined with spatial alignment cameras and air assist, you can cut, draw, engrave, and create with unmatched precision — all from one platform.

Bambu Lab H2D Specifications

| Feature | Specification |

|---|---|

| Build Volume | 325×320×325 mm (Single Nozzle) 300×320×325 mm (Dual Nozzle) |

| Max Nozzle Temp | 350 °C |

| Max Heatbed Temp | 120 °C |

| Max Chamber Temp | 65 °C |

| Extruder | Hardened Steel Gear, Built-in Cutter, PMSM Motor |

| Nozzle | Hardened Steel, Sizes: 0.2 / 0.4 / 0.6 / 0.8 mm |

| Frame | Aluminum & Steel Chassis, Plastic & Glass Enclosure |

| Motion System | Dual Toolhead with Smart Calibration |

| First Layer Calibration | Fully Automatic |

| Filament Diameter | 1.75 mm |

| Supported Materials | PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, PA, CF/GF, PPS |

| Air Purification | HEPA H12, G3 Pre-filter, Carbon Filter |

| Wi-Fi | 2.4 / 5 GHz Supported |

| Ethernet | Not Available |

| Touchscreen | 5" 720×1280 |

| Software | Bambu Studio |

| Connectivity | Wi-Fi, USB |

| Remote Monitoring | Supported (Multiple Onboard Cameras) |

| Filament Sensors | Runout, Tangle, Odometry |

| Power Supply | 2200 W @ 220V |

| Weight | 31 kg |

| Printer Dimensions | 492 × 514 × 626 mm |

| Accessories | Build Plate, AMS 2 Pro, Laser/Cutting Modules (Optional) |

.png)

SIGN UP

Drop Us A Line

We’re happy to answer any questions you have or provide you with an estimate. Just send us a message in the form below with any questions you may have.