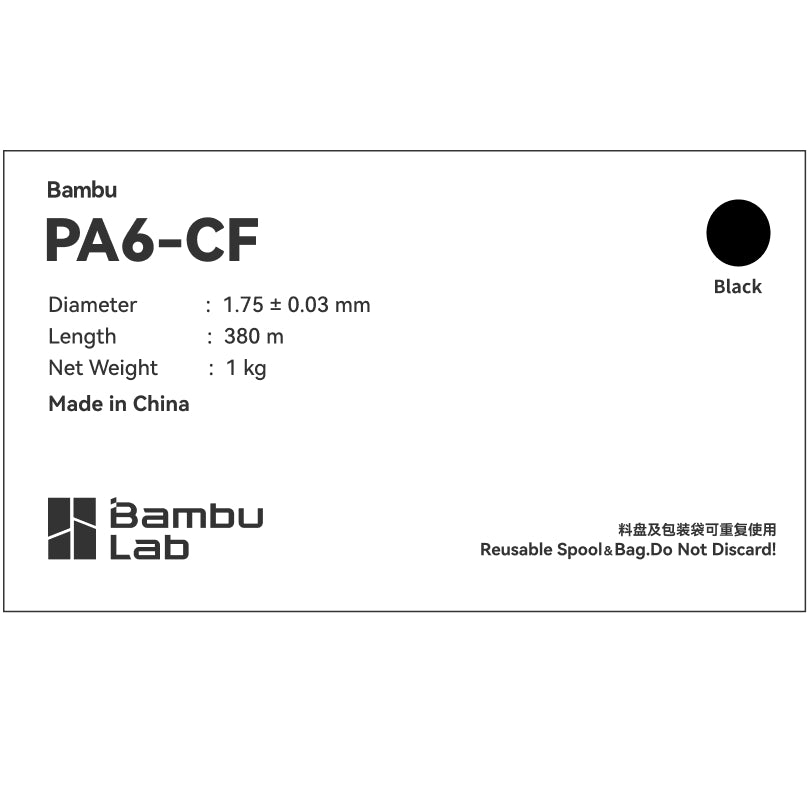

Bambu PA6-CF

SKU: N05-K0-1.75-1000-SPL

VENDOR: Bambu Lab

Pickup available at 7A Kent Street, Yarraville, VIC.

Usually ready in 4 hours if in stock

Bambu PA6-CF

Black / 1 Kg

7A Kent Street, Yarraville, VIC

7A Kent Street

Yarraville VIC 3013

Australia

03 9687 8638

Product Features

- Superior Strength and Stiffness

- Toughness & Vibration Resistance

- Exceptional Thermal Resistance

- Comes with High Temperature Reusable Spool

- Diameter: 1.75mm +/- 0.03mm

Cautions for use

- NOT compatible with 0.2 mm Nozzle

- Stainless Steel Nozzle NOT Recommended

- Dry before Use

- NOT AMS Compatible

Mechanical Properties Comparison

| Normal PA-CF | PA6-CF | Improved % | |

| Bending Strength - XY/MPa (Dry) | 128 | 151 | 18% |

| Bending Modulus - XY/MPa (Dry) | 4420 | 5460 | 24% |

*Both PA-CF and PAHT-CF need to be dried at 80 °C for 12 hours before printing.

Impact & Vibration Resistance

Bambu PA6-CF offers excellent impact resistance, ensuring effective vibration resistance for your prints. It is commonly used to print models that need to withstand impact, collision, and vibration.

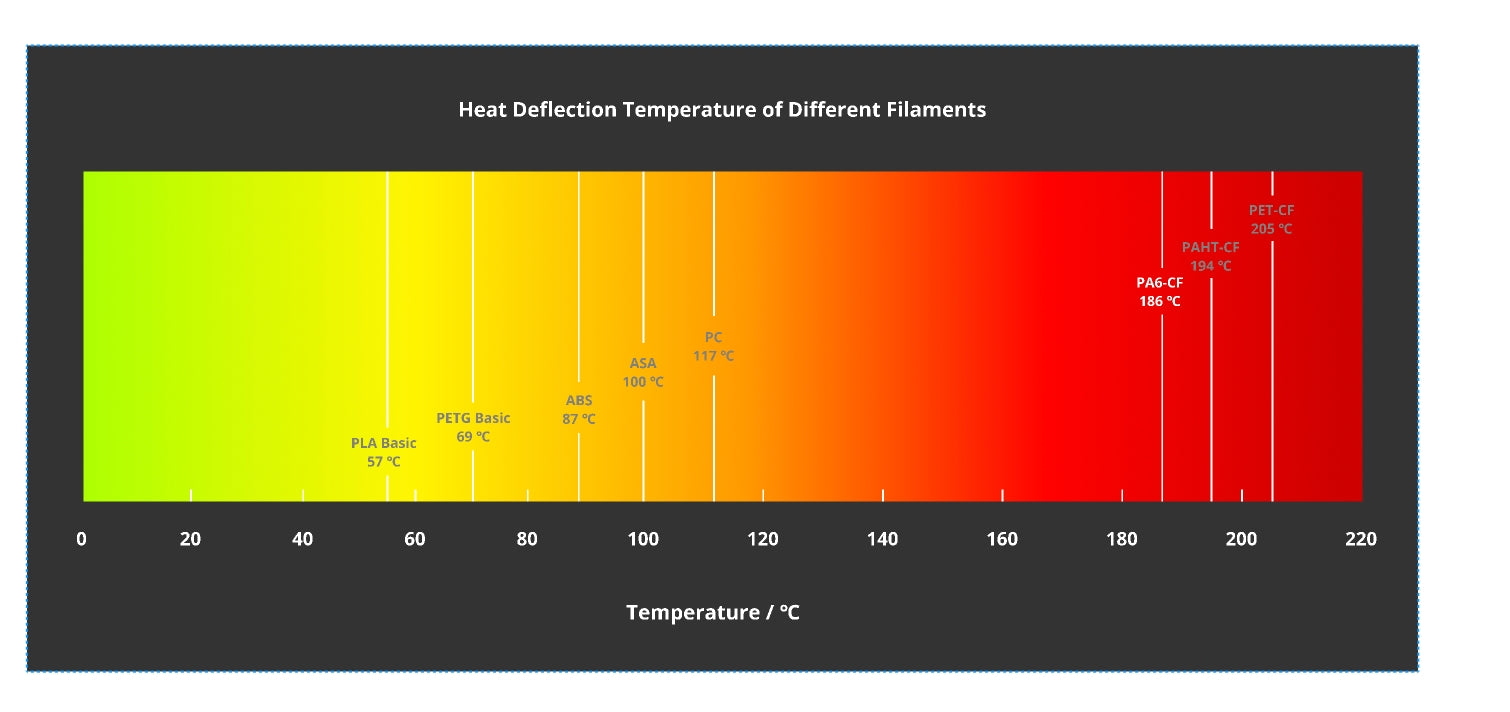

Exceptional Thermal Resistance

| Filament | PLA Basic | PETG Basic | ABS | ASA | PC | PA6-CF | PAHT-CF | PET-CF |

| Heat Deflection Temperature / ℃ (0.45 MPa) | 57 ℃ | 69 ℃ | 87 ℃ | 100 ℃ | 117 ℃ | 186 ℃ | 194 ℃ | 205 ℃ |

Parameters Comparison

| Normal PA6-CF | PA6-CF | PAHT-CF | |

| Composition | Nylon 6, carbon fiber | Nylon 6, carbon fiber | PA12 and other long-chain PA, carbon fiber |

| AMS Compatibility | NO | NO | YES |

| Dry Out Before Use | Required | Required | Required |

| Printing Speed | < 100 mm/s | < 100 mm/s | < 100 mm/s |

| Printer Type | Enclosure | Enclosure | Enclosure |

| Toughness (Impact Strength - XY, dry state) | 35.7 kJ/m² | 40.3 kJ/m² | 57.5 kJ/m² |

| Toughness (Impact Strength - XY, wet state) | 65.4 kJ/m² | 57.2 kJ/m² | 62.3 kJ/m² |

| Strength (Bending Strength - XY, dry state) | 141 MPa | 151 MPa | 125 MPa |

| Strength (Bending Strength - XY, wet state) | 67 MPa | 95 MPa | 115 MPa |

| Layer Strength (Bending Strength - Z, dry state) | 72 MPa | 80 MPa | 61 MPa |

| Layer Strength (Bending Strength - Z, wet state) | 31 MPa | 45 MPa | 49 MPa |

| Stiffness (Bending Modulus - XY, dry state) | 4870 MPa | 5460 MPa | 4230 MPa |

| Stiffness (Bending Modulus - XY, wet state) | 1890 MPa | 3560 MPa | 3640 MPa |

| Layer Adhesion (Impact Strength - Z, dry state) | 11.6 kJ/m² | 15.5 kJ/m² | 13.3 kJ/m² |

| Heat Resistant(HDT, 0.45 MPa) | 177 ℃ | 186 ℃ | 194 ℃ |

| Saturated Water Absorption Rate / % (25 °C,55% RH) | 3.80 | 2.35 | 0.88 |

Accessory Compatibility

| Recommended | Not Recommended | |

| Build Plate | Engineering Plate, High Temperature Plate or Textured PEI Plate | Cool Plate |

| Hotend | Hotend with Hardened Steel Nozzle (0.6 mm/ 0.4 mm (recommended) / 0.8 mm) | Hotend with Stainless Steel Nozzle (all size) Hotend with Hardened Steel Nozzle (0.2 mm) |

| Glue | Glue Stick Bambu Liquid Glue |

/ |

Recommended Printing Settings |

Physical Properties |

Mechanical Properties |

|||||

| Drying Settings (Blast Drying Oven) | 80 °C,8 -12h | Density | 1.09 g/cm³ | Tensile Strength | 102 ± 7 MPa | ||

| Printing and Keeping Container's Humidity | < 20% RH (Sealed, with Desiccant) | Vicat Softening Temperature | 212 °C | Breaking Elongation Rate | 5.8± 1.6 % | ||

| Nozzle Temperature | 260 - 290 °C | Heat Deflection Temperature | 186 °C | Bending Modulus | 5460 ± 280 MPa | ||

| Bed Temperature (with Glue) | 80-100 °C | Melting Temperature | 223 °C | Bending Strength | 151 ± 8 MPa | ||

| Printing Speed | < 100 mm/s | Melt Index | 6.8 ± 0.6 g/10 min | Impact Strength | 40.3 ± 2.5 kJ/m² | ||

What's in the Box:

|

|

|

|

Filament x1 & Desiccant x1 |

Package x1 |

Filament Label x1 |